core filling machine chocolate core filling machine extruder line

Core filling snacks food extruder production line from the raw materials, extrusion, core filling, press shapes, cutting, coating, flavouring can be finished one time, high automation.

Main Features:

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.Twin Screw Extruder corn Puff Snack Cheese ball making machine.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.Corn Puff Snack Processing Line with Cheap Price

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

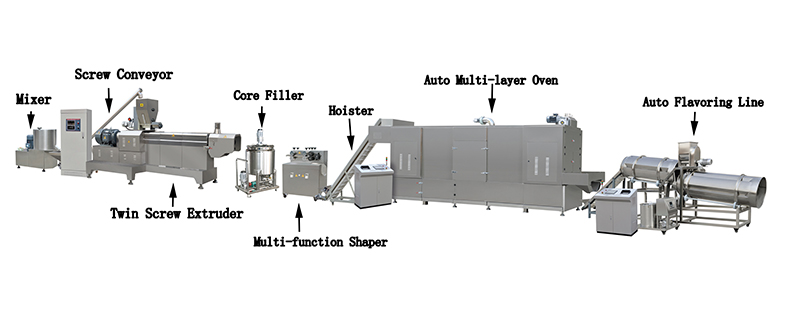

Flow chart:

Mixing---Extrusion system--Cutting-- -Drying system----Flavoring system---Packing system

parameter

Model | Installed power | Power consumption | Output | Cover an area | Water consumption | Operator |

DS65 Puffed snack production line | 80kw | 60kw | 120-150kg/h | 80m² | ≤30kg/h | 2-3persons |

DS70 Puffed snack production line | 105kw | 85kw | 200-300kg/h | 120m² | ≤60kg/h | 2-3persons |

DS85 Puffed snack production line | 125kw | 105kw | 300-500kg/h | 150m² | ≤100kg/h | 2-3persons |

Raw Material:

Corn, rice, millets, wheat, oat, barley etc as ingredients. Please note that all the materials should be in powder(flour) or grits form.

For filling: cream, chocolate, fruit paste, date paste, jelly, etc.

Final product:

for core filling snacks food, variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder