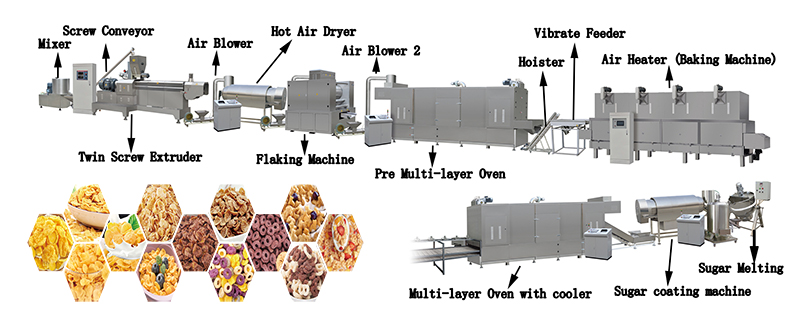

Advanced Cornflakes Breakfast Cereal Processing Line

Breakfast cereal corn flakes is a brittle food with good rehydration, outside the red is not bad, taste lubricants, grain flavor is fragrant. Corn flakes mainly corn flour as the main raw material, add sugar, vitamins, mixed raw minerals, add a sufficient amount of water after kneading, aging, forming, baking and tableting in order to manufacture a sheet flavoring.

Machine flow chart

Mixing system---Extrusion system----Cooling system—Flaking system--Drying system—Toasted system---Sugar Spraying system ---Drying system---- Packing system

Machine features

1. Mixer : Make the corn residue or corn flour added to a nutritional additive and mixing a proportion of water uniformly.

2. Screw conveyor : Marinated raw material fed to the extruder feed hopper.

3. Double screw extruder: The material in the feed hopper into the extrusion system, to produce small spherical particles.

4. Shaker: Dispersed particles, to avoid overlap pressed together into a tableting machine.

5. Air conveyor: Transported the particles into the tableting machine.

6. Flaking machine: Flaking the corn ball to raw corn flakes.

7. Air conveyor: Transfer the corn flakes to the baking oven.

8. Mutil-layer oven: Oven mostly is toaster, temperature between 0-200 degrees self-regulation through the control cabinet, internal stainless steel double mesh bag,baking time may be adjusted according to the speed, remove the water.