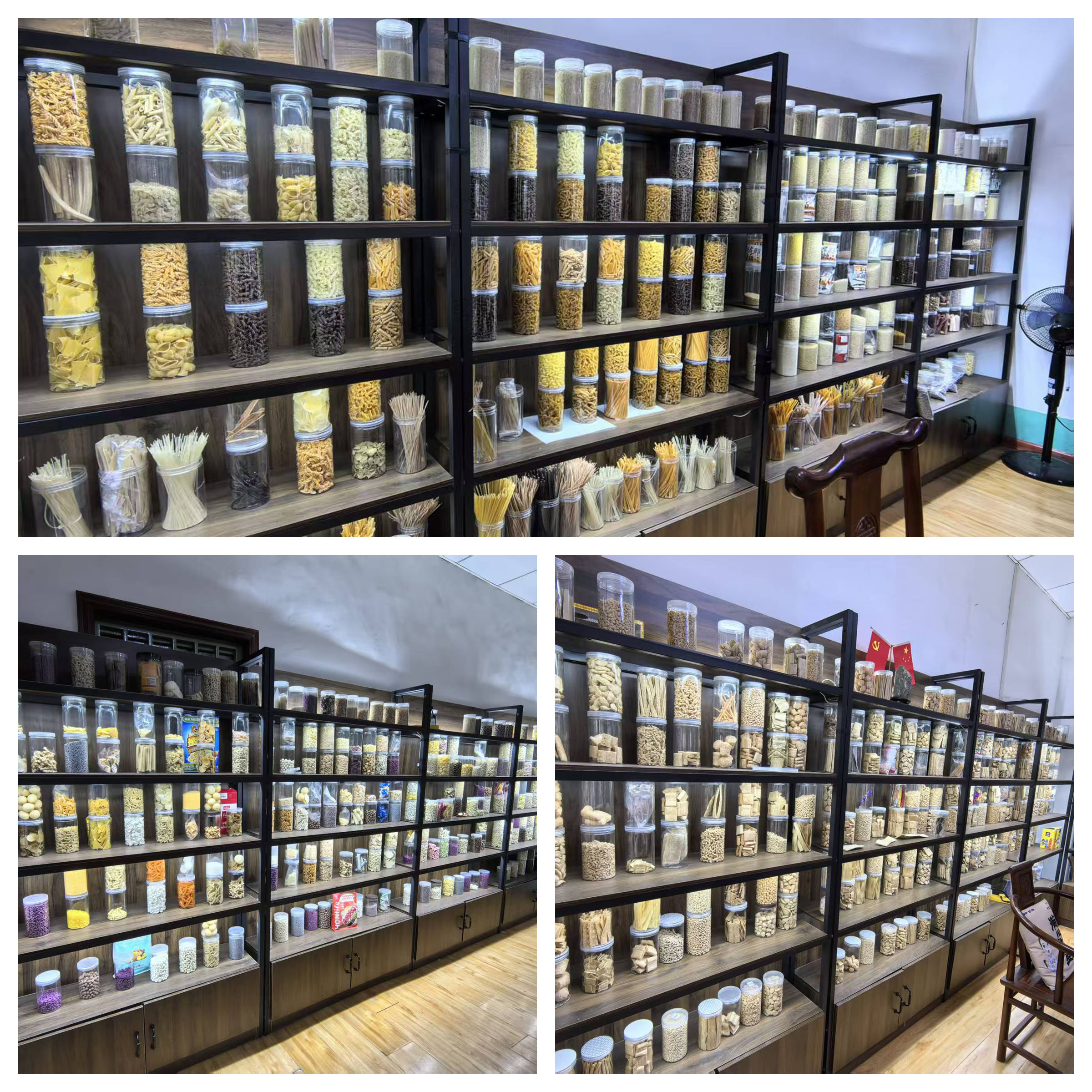

New show room with lots of new sample

Twin screw extruder is a widely used production and processing equipment in the food and feed industries. Its suitable raw materials mainly include powder or grain grains, starch, and some animal fat. According to product requirements, multiple materials can also be mixed for use; This equipment uses twin screw extrusion to process the material under reasonable temperature, pressure, and cutting force, allowing the material to be extruded and shape through a mold. During this process, the material undergoes a series of physical and chemical changes such as expansion, and secondary shaping. Twin screw extruder products are widely used, mainly including casual puffed foods, breakfast cereal, soy protein, artificial rice, pet food, pre gelatinized modified starch, etc. With technological progress, more and more traditional production methods have been replaced by twin screw extrusion technology. Compared to food processing methods such as cooking, baking, and frying, its main advantages are high automation, multi-purpose machine Large single machine output and low energy consumption under the same output.

The twin screw extruder is mainly composed of six parts: extrusion system, electric control system, temperature control system, transmission system, feeding system, and shaping system; It can also be equipped with a vapor conditioning system for wet puffed production as needed. By designing different structures and slenderness ratios according to product needs, screw extrusion systems can meet different process requirements. In actual production, only the production parameters need to be set, and various systems automatically work together, with strong stability and reliable quality.

Material: The feeding system and surface are made of SS304; The shelf and some parts are made of carbon steel; The screw and knife are made of high-strength alloy steel material

Temperature control method: Electric heating/steam heating; Water cooling (optional)

Control method: Independent electric control cabinet control; inverter control

Applicable raw materials: Corn flour, rice flour, flour and other powdered grains; Extracts from grains such as starch and wheat bran; Chicken, fish, pork

Application: Cereal, puffed snacks, baby food, pre gelatinized modified starch, pet food, fish feed, etc

Huaxin Shengda is a manufacturer of better quality extrusion technology for food industries, pet food industries, fish feed industries. We have well-experienced managers, outstanding engineers and well-trained technical workers providing specialist designs and practical solutions for a wide range of process needs. By constant technical exchange with well known firms of the same line in the world and also by introduction of advanced techniques and experiences into our company, we have established a strong technical guarantee system. In our management, it adheres to the principle of whole-hearted attitude, good credit, excellent quality and perfect service, and exerts strict quality control in production, sales and after-sales service. We base our products development and improvement on the suggestions and demands of our customers.

Our products consist of twin screw extruder, single screw extruder, dryer, roast oven, fryer, flavoring line, puff snacks/core filled snacks production line, corn flakes production line, breakfast cereal production line, bread crumb production line, nutritional powder/ baby food production line, corn chips/bugles production line, TVP/TSP/Meat Analogue production line, vegetarian meat production line,2D/3D pellet chips production line, artifical rice production line, modified starch/ pregelatinized starch production line, kurkure/ cheetos production line, rice crackers/ biscuit production line, instant noodles production line. Tortilla corn chips production line. We can also provide special design and product according to the clients` special requirements.