core filled snack production line order from south africe client

last month, we received the order from a south africe client for core filled snack production line, with a capacity of 150-200 kg per hour.

Currently, the production is completed, After showing the inspection running to customer, the production line is running well and with good performance. the customer is very satisfied with the machines. And ask us to load the container.

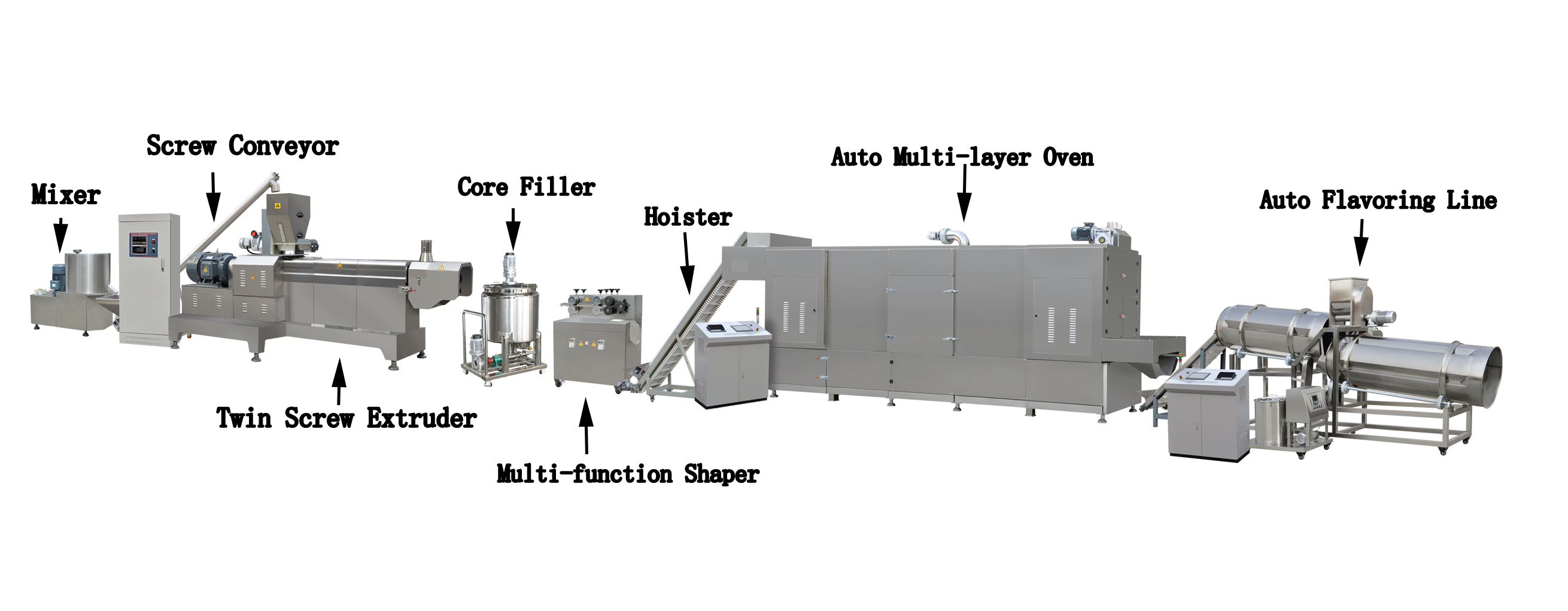

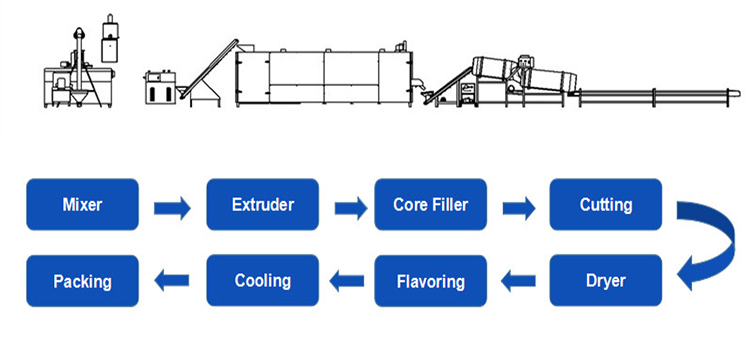

Corn-filling snacks food production line uses twin screw extruder to make hollow puffed snacks ,while the core filler injecting machine injects cream, chocolate, peanut butter etc into the snacks. Different flavors core fillers is injected into the snacks food that achieve co-extrusion, and enrich its taste of puffed snacks. The notch of the extruded snacks can be rolled cut or vertical cut and opened or sealed mouth. The fully automatic production flow included: Raw material feeding, extrusion puffing, core-filling, shaping, baking, coating etc. In addition, we also can produce non-fried snacks food with various shapes and fried snacks food by changing different molds.

Parameter

Model | Installed power | Power consumption | Output | Cover an area | Water consumption | Operator |

DS65 Puffed snack production line | 80kw | 60kw | 120-150kg/h | 80m² | ≤30kg/h | 2-3persons |

DS70 Puffed snack production line | 105kw | 85kw | 200-300kg/h | 120m² | ≤60kg/h | 2-3persons |

DS85 Puffed snack production line | 125kw | 105kw | 300-500kg/h | 150m² | ≤100kg/h | 2-3persons |