Automatic Corn Flakes Breakfast Cereal Production Line

Breakfast Cereal Corn Flake Machine Corn Flakes Production Line is a fully automatic processing line which is designed and developed from our company combining with European advanced technology.

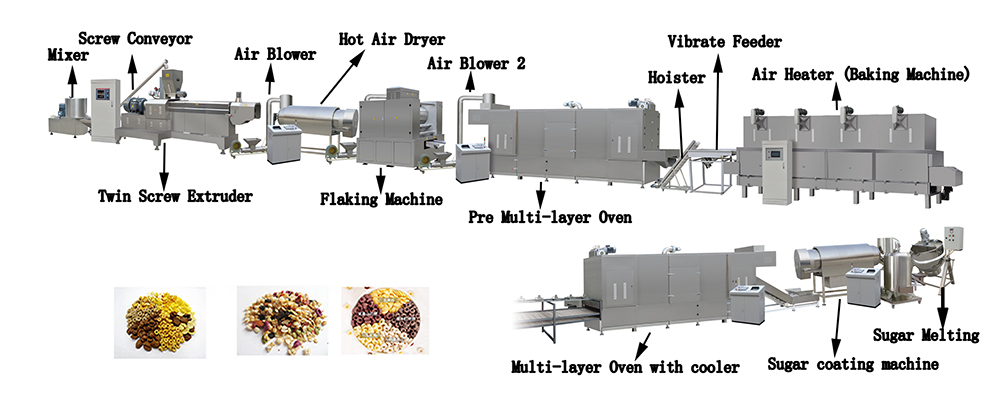

The production line uses corn flour, wheat flour, oat etc as its raw material. By twin screw extruder to accomplish cook curing, pelleting etc. Then by flakes pressing, baking, coating and other technological process to produce instant-eat crispy breakfast cereal corn flakes with regular, sweet, salty etc flavors.

Its breakthrough solves various difficult problem compared with domestic equipment, for example: pressing rollers sticking, low capacity of flakes pressing, low shaping rate, poor taste etc. Scientific processing technique can keep cereals nutritional elements.

Reasonable equipments collocation and realizable process control ensure to produce nutritional crispy breakfast cereal corn flakes with various shapes and sizes.

The processing line not only can reduce costs, but also can improves market competitiveness.

1. breakfast cereal corn flake machine main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Inverter ( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta, Pioneer, CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Dyer & Baking Machine source can be designed use Electricity, Gas, Oil or stream.

6. Machine material generally is Food grade stainless steel, also can customized as require.

7. Guarantee Time is 2 year.

8. After-sales Service Provided: Free spare parts, Field installation, Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Technical Parameter

Model parameter | DS65 Corn flakes production line | DS75 Corn flakes production line | DS85 Corn flakes production line |

Installed power | 180kw | 200kw | 240kw |

Power consumption | 126kw | 140kw | 168kw |

output | 120-150kg/h | 200-300kg/h | |

Length | 48m | 58m | 68m |

Flow chart

Our Services

About installation and after-sale service system

1. We can provide factory layout according to customer’s factory size in advance.

2. When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the processing line arrived your country,

and we will send two engineers to go and help you to install the line, teach your worker(3-4 workers) how to operate the line, until your worker know the 3D line well.

3. Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc.

and we have responsibility to provide technology support with you forever.

4. Our engineers can provide basic formula for producing the snack food etc. and help customer to produce good quality food according customer’s detailed formula.

5. We provide the spare parts will at preferential price for an extended long time.

6. other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f). Free new production techniques and formulas;

g). Provide 2 year complete warrantee and life-time maintance service;